In today’s competitive market, brand visibility is more important than ever. Customising your travel essentials, including bags, luggage, and accessories, is a powerful way to enhance brand recognition, foster customer loyalty, and create a lasting impression. Whether you're providing corporate gifts, team merchandise, or promotional giveaways, customised products serve as effective marketing tools that reinforce your brand identity every time they are used.

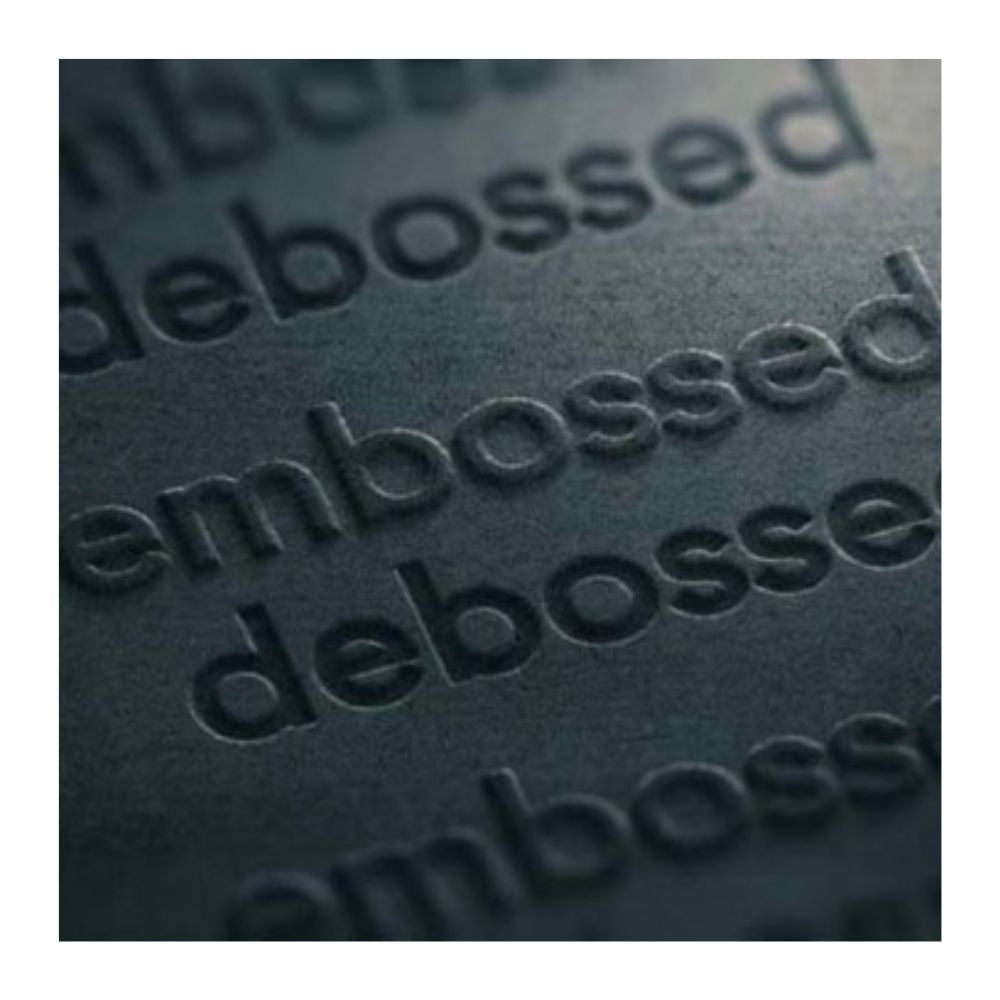

At Travelsupplies, we offer a diverse range of customisation options to suit different branding needs and material types. From classic screen printing and embroidery to advanced UV printing and hot stamping, we ensure your logo is displayed in the most impactful and durable manner. Our expertise in customisation allows us to provide high-quality branding solutions that align with your business objectives. Here are some of the customisation methods we use: